The current version of the Tecniplast website doesn't match your region. Please visit your local website to find information and offerings specific to your country.

The current version of the Tecniplast website doesn't match your region. Please visit your local website to find information and offerings specific to your country.

IWT has been a leader for cleaning equipment in the laboratory animal industry for decades, and our rack washer portfolio has always been the star.

IWT has been a leader for cleaning equipment in the laboratory animal industry for decades, and our rack washer portfolio has always been the star.

The Atlantis generation has been the benchmark among cage and rack washers in the LAS industry for years, as it has succeeded in providing the market with a set of solutions which minimize operational footprint, reduce energy and water consumptions, improve user experience while increasing throughput and general washing performance and ensuring flexibility to match various customer needs.

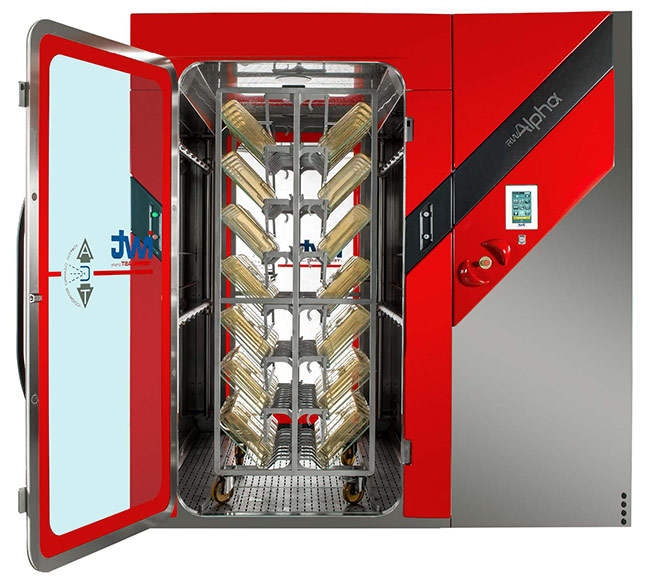

The recent launch of the new rack washer Alpha introduced key new features aiming to boost differentiation in the cage processing thus reinforcing Tecniplast positioning as the true innovation partner for the LAS market.

The new Adaptive Cleaning Technology, A.C.T., in brief, is an innovative system providing a unique cleaning arms control combining independent vertical and oscillating movements.

The new Adaptive Cleaning Technology, A.C.T., in brief, is an innovative system providing a unique cleaning arms control combining independent vertical and oscillating movements.

This feature ensures a superior coverage and targeted spraying pattern compared to traditional oscillating arm technology allowing operatives to optimize fluid-dynamic and minimize load-nozzles distance for a significantly increased mechanical wash force.

The direct spraying on all surfaces of the loaded items grants top-notch cleaning and rinsing efficiency, even when load density is significantly increased, making Alpha suitable for high-density presentation racks.

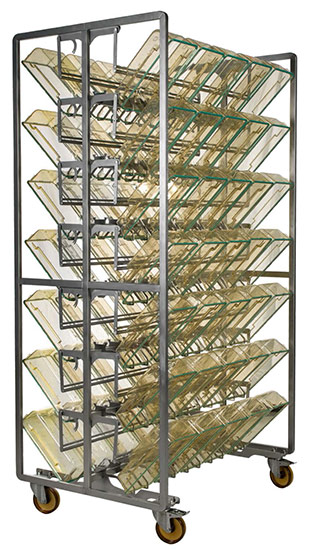

That’s why IWT developed its dedicated VHD presentation rack, turnkey solution to achieve unprecedented throughput capabilities while minimizing utilities consumptions, introducing unparalleled density capacities, up to 154 mice cages (EM500) per load.

High-density presentation racks in combination with Alpha's water flow, pressure and empowered coverage lead to exceptional cleaning performance, making it an ideal choice for medium to large-scale operations.

High-density presentation racks in combination with Alpha's water flow, pressure and empowered coverage lead to exceptional cleaning performance, making it an ideal choice for medium to large-scale operations.

Dealing with consumptions, results are even more outstanding: thanks to the enhanced water spraying pattern and the VHD presentation racks, Alpha has been able to achieve up to 75% savings per cage, with a water consumption of only 300ml (10oz), compared to previous generations of rack washers, and, given the new compact water tank design, over 13% energy savings.

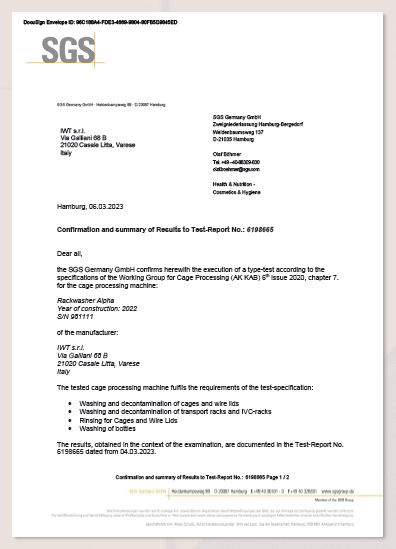

These outcomes would be meaningless without a third-party testing company that certifies the washing and rinsing of the Therefore, Alpha has recently been challenged in accordance with the current AK KAB protocol by SGS, one of the world’s leading inspection, verification, testing and certification companies, and has obtained the official certificate, thus demonstrating that Alpha fulfills the AK KAB requirements in providing efficient and effective washing, rinsing and decontamination!

These outcomes would be meaningless without a third-party testing company that certifies the washing and rinsing of the Therefore, Alpha has recently been challenged in accordance with the current AK KAB protocol by SGS, one of the world’s leading inspection, verification, testing and certification companies, and has obtained the official certificate, thus demonstrating that Alpha fulfills the AK KAB requirements in providing efficient and effective washing, rinsing and decontamination!

GIORGIO DALLERA

JUNIOR PRODUCT SPECIALIST - IWT S.R.L.