The current version of the Tecniplast website doesn't match your region. Please visit your local website to find information and offerings specific to your country.

The current version of the Tecniplast website doesn't match your region. Please visit your local website to find information and offerings specific to your country.

The US Patent and TradeMark Office certificated the uniqueness of Tecniplast’s Interceptor, granted the Patent n. US 10,412,927 B2, dated 17th September 2019.

The US Patent and TradeMark Office certificated the uniqueness of Tecniplast’s Interceptor, granted the Patent n. US 10,412,927 B2, dated 17th September 2019.

This important patent concerns a device for improved hygienic monitoring of individually ventilated caging (IVC) rack system for Laboratory Animals.

Moreover, the patent includes a method which allows the removal and transfer of the biological sample from inside the IVC rack in a contamination free manner by enabling a safe transfer of the sample to any further processing procedure for analysis outside the rack.

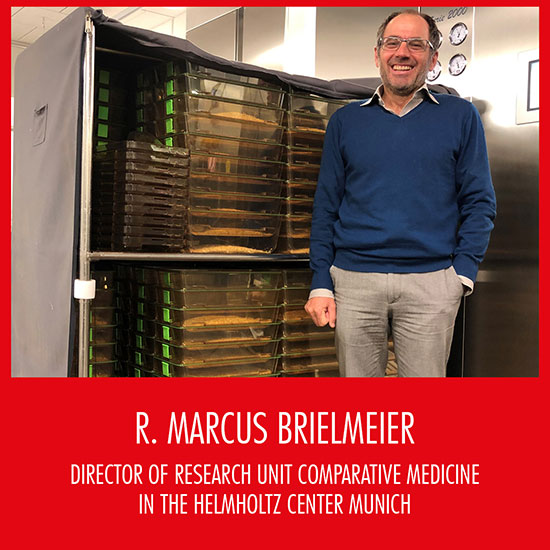

We had the great opportunity to interview one of the inventors of Intececeptor, Dr. Marcus Brielmeier, Director of Research Unit Comparative Medicine in the Helmholtz Center Munich who has been working side by side with the Tecniplast R&D team to realize and test the Interceptor.

Dear Dr Brielmeier, the US Patent and Trade Mark Office has published the Interceptor US concession certificate. Your name is the first one among the inventors. Can you comment this important news?

I feel very proud! After ten years of technology development and scientific studies this is a very important milestone.

Can you describe the functionalities of Interceptor to our readers?

Can you describe the functionalities of Interceptor to our readers?

The device samples exhaust air particles coming from all the mice kept in one or more IVC racks connected to one air handling unit testing the sample by PCR technology allows sensitive detection of infectious agents potentially infecting the mice. We and others have shown in a series of studies that the sensitivity, the speed and reliability of detection outperforms the method of sentinel monitoring by far. Eventually this has been shown for the most prevalent agents found in contemporary mouse colonies.

As already said, this method allows the removal and transfer of the biological sample from inside the IVC rack in a contamination free manner by enabling a safe transfer of the sample to any further processing procedure for analysis outside the rack. What are the benefits of this solution for Lab Animal facility mangers and technicians?

This is a very important feature of the technology for several reasons. (In contrast to other products on the market!). Most importantly, when using PCR technology it is vital to exclude the possibility of false positive results. When working with rodents categorized biosafety level 2 or higher, this becomes important also for workplace safety.

You developed this system together with Tecniplast. Can you comment the added value brought by Tecniplast organization and Tecniplast R&D innovation capabilities?

You developed this system together with Tecniplast. Can you comment the added value brought by Tecniplast organization and Tecniplast R&D innovation capabilities?

Without the continuous input of the Tecniplast engineers we would not have come to such a sophisticated (well engineered) product. Numerous prototype sampling devices have been produced in the Tecniplast workshops and tested by my scientific team.

I have concentrated as a laboratory animal scientist on better solutions for hygienic monitoring. Tecniplast was instrumental in all other aspects.

By the way, using exhaust air particle technology saves the lives of a large number of sentinel mice and therefore is a great contribution to the 3R's.

GABY DORNER

SALES MANAGER - TECNIPLAST GERMANY